COB (Chip-on-Board) is a new LED technology that can output maximum brightness with the same amount of power.

Does this sound very good?

Principle of COB: Multiple LED Chips (typically nine or more) bonded directly to the substrate by the manufacturer to form a module for a single higher LED array packing density, thereby increasing the "lumen density" (a very professional term used by optical engineers here).

The Ordinance work light is Olight UK's first COB LED light.

It is powerful:

1.200-3000 lumens flood light can be stepless dimming.

2. Colour Temperature: 2700k to 6000k.

3. In addition, it can be used continuously for 46.7 hours (about 2 days).

4. As a versatile work light with two color temperatures, it can be used for:

● Work, construction, maintenance, equipment inspection, maintenance,

● Outdoor, BBQ, camping, construction, road construction, etc.

It can be used in various situations.

Click to view:https://www.olightstore.uk/odiance-portable-led-work-light

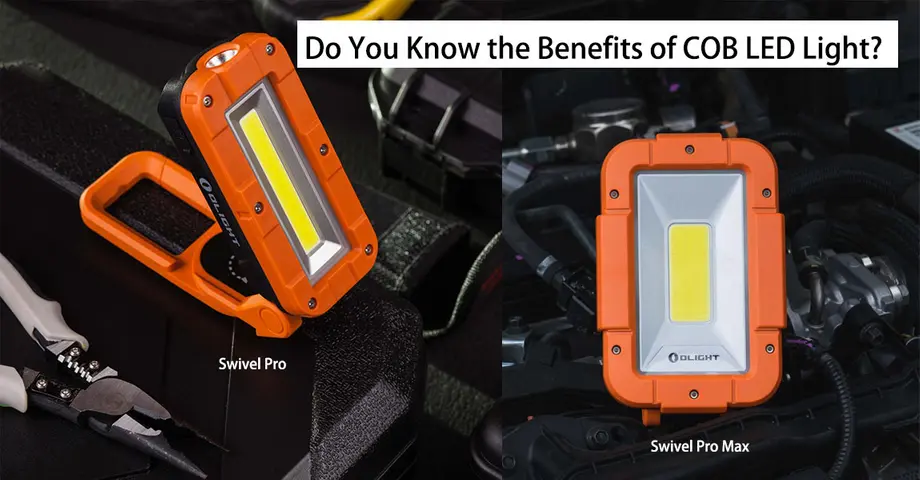

Swivel Pro/Swivel Pro Max is the second COB Light newly released by Olight UK official store (December 8, 2022)

Swivel Pro

1. Rotating and foldable COB work light

2. COB flood light: maximum 1100 lumens, can provide close-range lighting.

3. LED spotlight: maximum 220 lumens, for long-distance lighting

4. Type C charging method, the longest running time is 84 hours

Click to view:https://www.olightstore.uk/swivel-pro-cob-work-light

Swivel Pro Max

Swivel Pro Max is an upgraded version of Swivel

1. Rotating and foldable COB work light

2. COB floodlight: maximum 1600 lumens, can provide close-range lighting.

3. Type C charging method, the longest running time is 120 hours

Click to view:https://www.olightstore.uk/swivel-pro-max-cob-floodlight-work-light

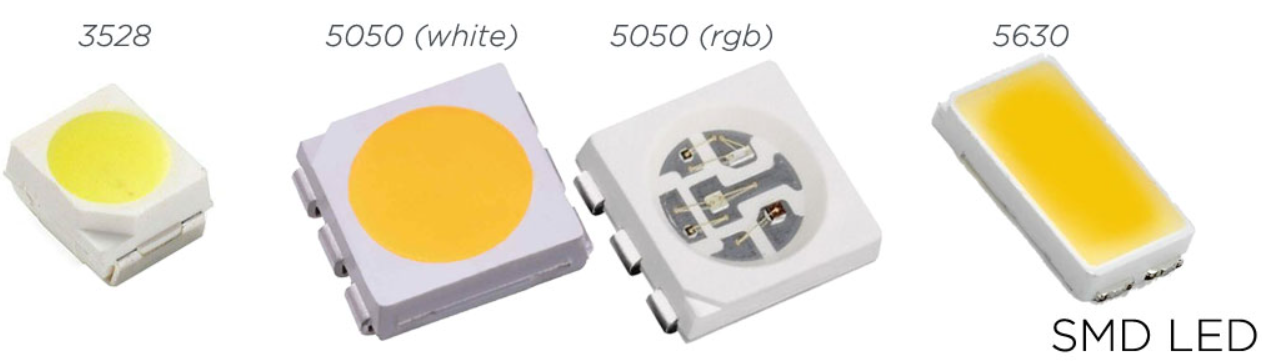

SMD LEDs and DIP LEDs are often compared to COBs.

DIP (Dual Inline Package)

Source:https://sep.yimg.com/ty/cdn/yhst-135552442550403/header-led-tech-compare-dip.jpg

DIP LEDs are a design that mounts a chip in a hard plastic bulbous head, with 2 straight parallel connecting pins. First developed by Nick Holonyak in 1962.

On average, the DIP can output 3-4 lumens per LED. Although this design is still used in some products today (e.g. rope light), it is much less efficient than newer LED chips such as Surface Mounted Device (SMD) and Chip-on-Board (COB) due to its optical decay and lower CRI.

SMD (Surface Mounted Device)

Source:https://sep.yimg.com/ty/cdn/yhst-135552442550403/header-led-tech-compare-smd.jpg

As mentioned above, SMD is a more advanced LED chip technology than DIP. It mounts the LEDs directly on the electronic board. Each chip uses 3 to 9 diodes and produces more lumens per watt than the original DIP LEDs and the service life is longer.

COB vs SMD VS DIP

Source: https://siliconlightworks.com/image/data/Graphics/LED%20Array%20Packing%20Density%20Comparison.jpg

Compared to the old SMD LED technology and DIP LED technology, using COB LED technology on the same board area will increase the number of LEDs many times.

Using COB LED technology can also greatly reduce the footprint and energy consumption of the LED array while keeping the light output constant.

Another big difference between COB and other LED technologies is that COB devices have only 1 circuit and 2 contacts for the entire chip regardless of the number of diodes, and this single circuit design simplifies the rest of the LED device.

Advantages of Chip-on-Board

1. Smaller size and brighter

COB LEDs are mounted with multiple small chips, and the number of diodes mounted within each chip is much larger than that of SMDs and DIPs (most COB LEDs contain 9 or more diodes, while most SMD LEDs only have 3 diodes, and DIP LEDs only have 1 diodes), the density between the diodes is more compact and takes up less area of the device but it can emit many times the light source in the same area as a normal LED light, which shows the maximum potential of LED Chips, increasing the lumen output per square inch.

2. Lighting is more uniform

COB lighting is more uniform and it can be used as a floodlight for indoor lighting, floodlights, photography, camera lighting, etc.

3. Improve the efficiency of converting electricity into light

Traditional DIP LEDs can only output 20-50 lumens per watt, but COB LEDs can output up to 100 lumens per watt, emitting higher brightness with lower power consumption.

4. Good heat dissipation

Since a single circuit design using two contacts can power multiple diodes accommodated by the COB light, resulting in fewer operating components, the heat generated by each LED chip can be reduced, thereby extending the lifespan and enhancing the stability and reliability of the COB light.

5. Low failure rate

Since each chip is directly mounted on the substrate, there is no need for spot welding of individual LED chips. The lower the number of solder joints, the lower the failure rate.

Application of COB LED Lights

COB LED lights can make high power LED flood lights. It can be used in small devices such as cameras and smart phones, and generally also appears in ports, factories, warehouses, industrial areas, street lights, parking lots and other places that require large-area lighting.

Of course, COB led lights also have the disadvantage that they are currently only available in a limited variety of colors (blue, green, pink, red, cool white, neutral white and warm white)

Summarize

Despite the above shortcomings, it still does not affect the important role of COB in LED lighting. Because historically, the lighting brightness of lamps has been limited by the power supply time of the electricity. Generally speaking, the higher the brightness of the light, the more electricity required, the shorter the operation time of the light. However COB light is reducing the conflict between brightness and power.

Statement: the image inserted in this article is for display only, and the source of the image is remarked. If you feel that we have infringed your image copyright, please contact us to delete it, we will be very grateful!